Hardox 400 | Abrasion Resistant Plate | Hardox Plate Supplier Malaysia

கடைசியாக புதுப்பிக்கப்பட்டது

விலை:

R.F.Q

Share Product:

விவரம்

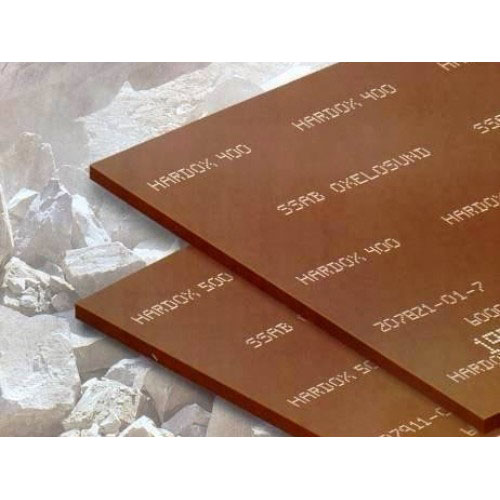

Hardox 400

HARDOX 400 is an abrasion resistant plate with a hardness of 400 HBW, intended for applications where demands are imposed on abrasion resistance in combination with good cold bending properties. HARDOX 400 offers very good weldability.

Hardness : 370 - 430 HBW

----------

Applications :

Crushers, sieves, feeders, measuring pockets, skips, cutting edges, conveyors, buckets, knives, gears, sprockets, dumptrucks, loaders, industrial trucks, lorries, bulldozers, excavators, slurry pipe systems, screw conveyors, presses etc.

----------

Mechanical Properties :

Yield strength : 1000MPa

Tensile strength : 1250MPa

Elongation : 10%

----------

Impact Properties :

Testing temperature :- 40 °C

Impact energy Charpy-V, longitudinal : 45(J)

----------

Dimensions :

HARDOX 400 is supplied in plate thicknesses of 3 -130 mm. More detailed information on dimensions is provided in our brochure 042-UK General Product Information WELDOX, HARDOX and ARMOX.

*) Plate thickness below 4 mm only after special agreement.

----------

Heat Treatment and Fabrication :

HARDOX 400 has obtained its mechanical properties by quenching and when necessary by means of subsequent tempering. The properties of the delivery condition can not be retained after exposure to service or preheating temperatures in excess of 250oC (480o F).

HARDOX 400 is not intended for further heat treatment. For information concerning welding and fabrication, see our brochures on www.hardox.com or consult our Technical Customer Service.

Appropriate health and safety precautions must be taken when welding, cutting, grinding or otherwise working on the product. Grinding, especially of primer coated plates, may produce dust with high particle concentration.

----------

Wear Resistance Steel Plate :

Chemical Properties :

| Grade | C (Max) | Mn (Max) | P (Max) | S (Max) | Si (Max) | Cr (Max) | Ni (Max) | Mo (Max) | B (Max) | V | Other Element |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Hardox 400 | 0.20 | 1.60 | 0.025 | - | 0.70 | 0.80 | 1.00 | 0.80 | 0.005 | - | |

| Sumihard K400 | 0.17 | 1.25 | 0.012 | 0.003 | 0.29 | 0.02 | 0.02 | 0.10 | 0.001 | - | |

| Welhard 400 | 0.22 | 2.00 | 0.250 | 0.01 | 0.55 | 1.20 | - | 0.60 | 0.005 | - | Nb-.05 |

| Fora 400 | 0.20 | 1.60 | 0.020 | 0.003 | 0.01 | 1.00 | 0.50 | 0.20 | 0.003 | - | |

| Raex 400 | 0.20 | 1.70 | 0.030 | 0.015 | 0.70 | 1.50 | 0.40 | 0.50 | 0.004 | - | Ai = 0.060 max |

| Xar 400 | 0.28 | 1.50 | 0.025 | 0.01 | 0.80 | 1.00 | 0.50 | 0.50 | 0.005 | ||

| Brinar 400 | 0.18 | 1.50 | 0.015 | 0.005 | 0.30 | 1.55 | 1.20 | 0.60 | 0.005 | - | Ai = .015 max |

| Dillidur 400 | 0.20 | 1.80 | 0.025 | 0.01 | 0.50 | 1.50 | 0.80 | 0.50 | 0.005 | 0.08 | Nb = .05 max |

| JFE EH360LE | 0.17 | 1.60 | 0.02 | 0.01 | 0.55 | 0.40 | - | 0.35 | 0.004 | 0.02 | |

| Quard 400 | 0.16 | 1.60 | 0.025 | 0.01 | 0.70 | 0.50 | 0.25 | 0.25 | 0.005 | - |

----------

Physical Properties :

| Grade | Origin | Tensile Strength | Yield Strength | Brinell Hardness | |

|---|---|---|---|---|---|

| Mpa | Mpa | Elongation in 2 inches (min.)% | |||

| Hardox 400 | Sweden | 1250 | 1000 | 10 | 360 - 440 |

| Sumihard K400 | Japan | 1322 | 1075 | 10 | 360 - 440 |

| Welhard 400 | Japan | 1236 | 1070 | 22 | Min 400 |

| Fora 400 | Belgium | 1350 | 1100 | 13 | 360 - 440 |

| Raex 400 | Finland | 1200 | 1000 | 10 | 360 - 420 |

| Xar 400 | Germany | 1250 | 1020 | 12 | 360 - 440 |

| Brinar 400 | Germany | 1300 | 1100 | 12 | 360 - 400 |

| Dillidur 400 | Germany | 1200 | 1000 | 12 | 370 - 430 |

| JFE EH360LE | Japan | 1308 | 1050 | 10 | 361 - 440 |

| Quard 400 | Belgium | 1250 | 1050 | 10 | 370 - 430 |

விவரக்குறிப்பு

பட்டியல் Download