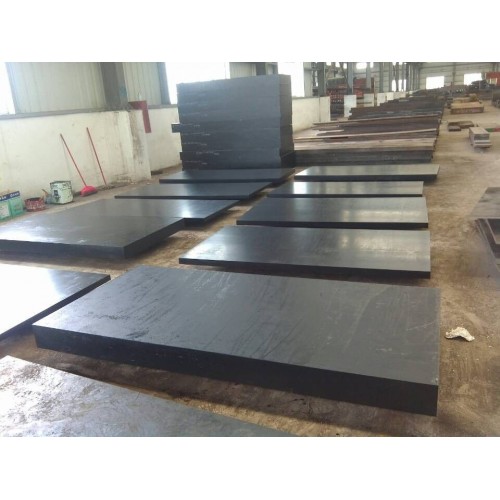

P20 Plastic Mould Steel | 1.2311 | Nak55 | P20+Ni | 618 equivalent

価格:

R.F.Q

DIN 2311 is the Pre Hardened Plastic mould steel hardness distributed evenly in large cross sections that have excellent weldability with least hardness elevation, good mirror polishability and less streak texture making finishing easier. Size Section availability upto 255mm thickness. Supply hardness is 240-280 BHN.

Share Product:

詳細

P20 Plastic Mould Steel (or known as 2311 Plastic Mould Steel)

Properties :

2311 Plastic Mould Steel / 3Cr2Mothat is usually supplied in a hardened and tempered condition. Good machinability, better polishability, compared to 1.2312 (AISI P20 S).

----------

Typical Applications :

P20 Plastic Mould Steel is mostly used for Plastic Moulds, Frames for Plastic Pressure Dies, Hydroforming Tools.

----------

| Related Specifications | |

|---|---|

| Germany | DIN 1.2311 |

| USA | AISI P20 |

----------

Chemical Composition :

| Carbon | 0.40% |

| Manganese | 1.50% |

| Chromium | 1.90% |

| Molybdenum | 0.20% |

----------

Soft Annealing :

| Temperature | 710 - 740°C |

| Cooling | furnace |

| Hardness | max 235 HB |

----------

Stress Relief Annealing :

| Temperature | 500 - 550°C |

| Cooling | furnace |

----------

Hardening :

| Temperature | 830 - 870°C |

| Cooling | Oil or Hot Bath [180 - 220°C] |

| Tempering | Refer to Tempering Diagram |

カタログ ダウンロードする